Infrared Absorption Studies Using Metal Micro Arrays

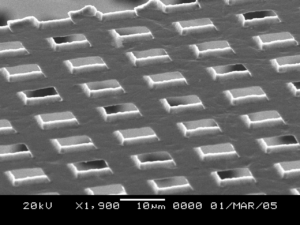

Consider a microwave oven. The door to microwave ovens has a glass window that has a metal screen covering it. The holes in the metal screen are several millimeters in diameter. The reason for this screen is very simple. The microwave radiation that is being generated inside the microwave oven has a frequency of 2450 MHz, which corresponds to about 12 cm or 120 mm.[1] It turns out that electromagnetic radiation can pass through metals as longs as the holes in the metals are larger than the wavelength of the electromagnetic radiation. In the case of our microwave ovens, the holes are smaller than the wavelength of the electromagnetic radiation and therefore the microwave radiation is reflected by the metal screen as if it were a solid sheet of metal.

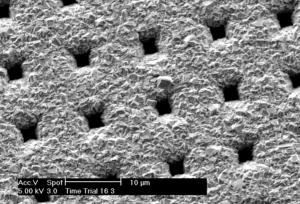

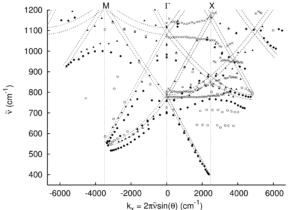

In the situation where the wavelength of the electromagnetic radiation and the size of the holes in a metal screen are nearly the same, a very interesting phenomenon can occur. When the two sizes are nearly the same, the size of the holes in the metal mesh, what metal the mesh is made out of, and the presence of any other substances adsorbed on the mesh can greatly effect the phenomenon. When several requirements are met, the metal mesh will convert the incident electromagnetic radiation into an excited surface plasmon polariton (SPP). This surface plasmon polariton can then transfer through the mesh to the other side where the mesh converts the excited SPP back to electromagnetic radiation that is emitted from the surface. This effect can result in a larger percent transmission through mesh than the percent open area of the mesh.

The study of surface plasmon polaritons in the infrared was the focus of my PhD research and remains of interest to both myself as well as other researchers.

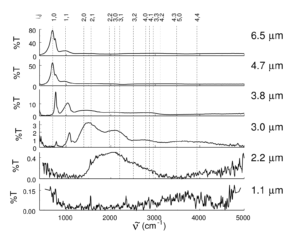

Transmission Properties vs Hole Size

Transmission Properties vs Metal

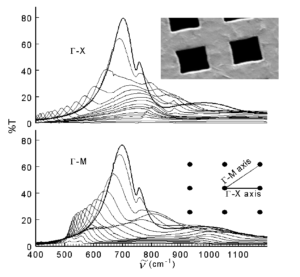

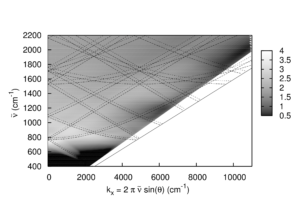

Transmission vs Angle of Incidence

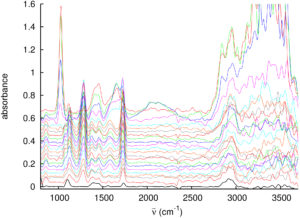

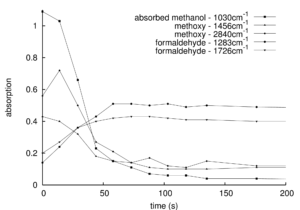

Absorbances Due to Adsorbed Surface Species